PC pumps

Solving wastewater problems the PC way

Blockages and failures occur more often with some pump types, but for many of today’s water operators, there is a solution. Here, we take a look at how progressive cavity (PC) pumps are solving some of the water industry’s key pumping challenges.

Pumps are integral to the successful operation of wastewater treatment works (WwTW). Whether moving untreated water, transferring dewatered sludge or metering chemicals, the pumps in use at WwTW need to be easy to monitor, robust, reliable and able to handle a variety of materials. But not all pumps are the same.

Blockages and failures occur more often with some pump types, and with water companies delivering efficiency savings that have resulted in more unmanned sites, the discovery of process problems can be delayed, sometimes resulting in pump downtime. For many of today's water operators, there is a solution. Here, we take a look at how progressive cavity (PC) pumps are solving some of the water industry’s key pumping challenges.

Monitoring and maintenance

Many of today’s WwTW were originally designed to be manually supervised by on-site operatives who checked for blockages, process or equipment problems and corrected them in a timely manner. Due to partial process automation, many sites are now unmanned, with maintenance planned at specific intervals.

When unforeseen problems occur, such as pump blockages due to ragging, or lack of suction lift due to grit contamination causing excessive pump wear, a maintenance team has to be despatched to rectify the issue. However, some PC pumps, such as SEEPEX’s Smart Conveying Technology (SCT) range, can be remotely monitored, making it easier for problems to be anticipated and enabling predictive maintenance.

For example, the use of variable frequency drives (VFD) and the ability to monitor speed means operators can foresee when maintenance will be required. As the pump stator wears, the pump speed increases; once this is identified, the SCT pump can be very quickly adjusted to match its original capacity, keeping efficiency high and providing more time to plan for maintenance.

Variable solids

Another key challenge at WwTW is the variable materials that need to be treated. Inputs can start from as little as 2% dry solids (ds) content; primary and secondary or activated sludge have a variable ds content of typically between 6-10%; while dewatered sludge has a ds content of anything between 20-45%. This range of viscosities can be a problem for some pump designs, which struggle to cope with viscous products. However, unlike many other pump types, PC pumps boast different designs of inlet suction casings and can therefore handle everything from very thin to highly viscous material, even those that do not flow, as well as abrasive and corrosive products.

Not only that, but the presence of a VFD in the Seepex PC pump range means that they can be speeded up or slowed down as required, resulting in predictable, regular, laminar flow despite varying ds content or viscosity. This results in a higher quality, more uniform sludge and also means less wear and tear on the pump itself, increasing its lifespan. The stable, variable flow rate also enables downstream equipment, such as thickeners and dewatering devices, to perform to their optimum operating conditions.

In addition, contamination is commonplace at WwTW, whether in the form of soft solids, grit, or rags (wipes). Some pump designs can be damaged or blocked by such materials, but due to their ability to handle solid particles, PC pumps are much better able to cope with such contaminants. Seepex’s SCT range, for example, is able to pass rags more efficiently and when blockages do occur, they can be cleared quickly by the rapid removal of half of the stator, without the need to dismantle any pipework.

Challenges

PC pumps can pump over long distances as they generate pressures up to 96 bar. This is particularly important for dewatered sludge, which has high friction losses in pipework due to its high ds%. Water operators are keen to increase the ds% of their dewatered sludge as it reduces disposal costs, but the thicker it becomes, the harder it is to pump, particularly over distance. The smart application of PC pumps, together with boundary layer PC dosing pumps, reduces friction losses to help to cut sludge disposal costs for operators. Another pumping issue at WwTW is the need to lift liquids from the base of settlement tanks. Some traditional pump types struggle with this request but PC pumps have excellent suction lift capabilities and can handle this task with ease. This means that pumps can be surface-mounted, removing the maintenance overhead associated with dry well working. This is especially valuable on unmanned sites.

PC pumps are virtually pulsationfree. They use a rotor/stator pumping action which delivers a continuous flow into the product stream, compared to the start/ stop action of piston or other positive displacement pumps. In the case of Seepex’s smart PC dosing pumps, this produces a stable flow rate with a linear accuracy of +/-1%. This is particularly important when metering or dosing chemicals and flocculants.

Furthermore, when dewatered sludge is transferred to central sludge treatment centres, it often needs to be back-mixed, to ensure the ds content is low enough for onward processing; a ds content of 16% is preferred for anaerobic digestion, for instance. Some PC pump solutions, such as the Seepex T range, linked to a BN pump, can add liquid and mix in the same pump to the correct ds%, regardless of variable inputs, making them particularly suitable for back-mixing applications.

The final problem that PC pumps can help to solve is one which is of increasing concern to water operators is energy inefficiency. Unlike piston pumps, PC pumps produce low pulsation flow and require much smaller drives and motors. And unlike air-operated pumps, they only run when needed. In addition, Seepex’s SCT range of PC pumps delivers further energy savings of up to 20% compared to traditional PC pumps, benefitting both planet and pocket.

Dewatered sludge

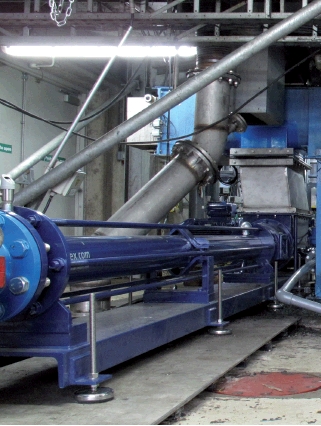

Thames Water is the UK’s largest water and sewage treatment company. Engineers at the company’s Reading sewage treatment works identified that if they increased the ds content of their dewatered sludge from 22% to 25% it would cut disposal costs. However, they needed reliable pumps to transfer the dewatered sludge over 80m without increasing system costs. The piston pumps currently in use were identified as a limitation due to their frequent maintenance requirements and the high pressures they generated. Additionally, they used 31kW of power, all of which added up to a high cost of ownership for Thames Water.

Seepex supplied open hopper PC pumps to transfer the higher ds% sludge, in the process delivering a 50% reduction in power consumption and up to 75% reduced discharge pressure. And since they were installed 36 months ago, they have required no maintenance interventions. The Seepex system has therefore delivered a hat-trick of cost reductions for Thames Water: lower sludge disposal costs, lower energy use and reduced maintenance costs.

“PC pumps can pump over long distances as they generate pressures up to 96 bar.”